The electric scooter motor is a key component. When buying a scooter, deciding on the motor type will be one of the biggest decisions you will have to make.

That’s why I made a complete introduction and technical guide to electric scooter motors to help you understand everything you need to know about them.

Electric scooter motors

Electric scooter motors typically range from 250W to 2000W or higher. Key distinctions include real power vs. peak power, hub vs. chain-drive motors, geared vs. gearless hub motors, and brushed vs. brushless DC motors.

How do electric scooter motors work?

How motors work depends on their type. In general, the motor listens for your input through a component known as the controller. When you hit the throttle on your handlebar, the controller sends a signal to the motor to start running.

Then the motor draws energy from the battery and starts to move.

The most common motor found in the everyday commuting scooter is a brushless DC, gearless hub motor. This is a very helpful video that explains how it works.

Electric scooter motor specifications

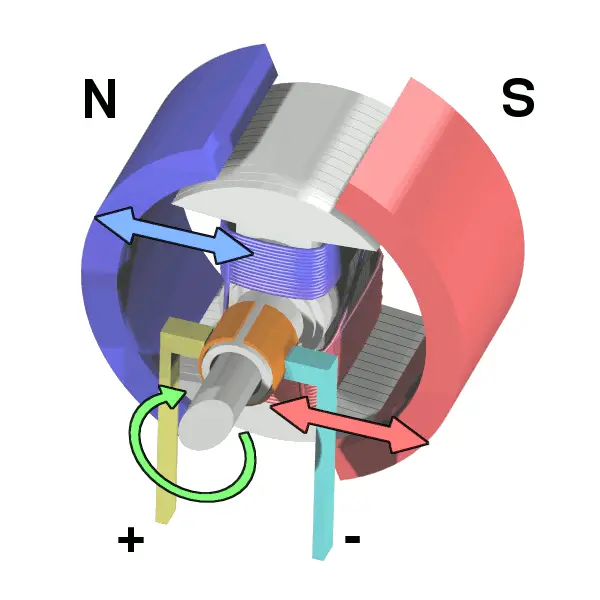

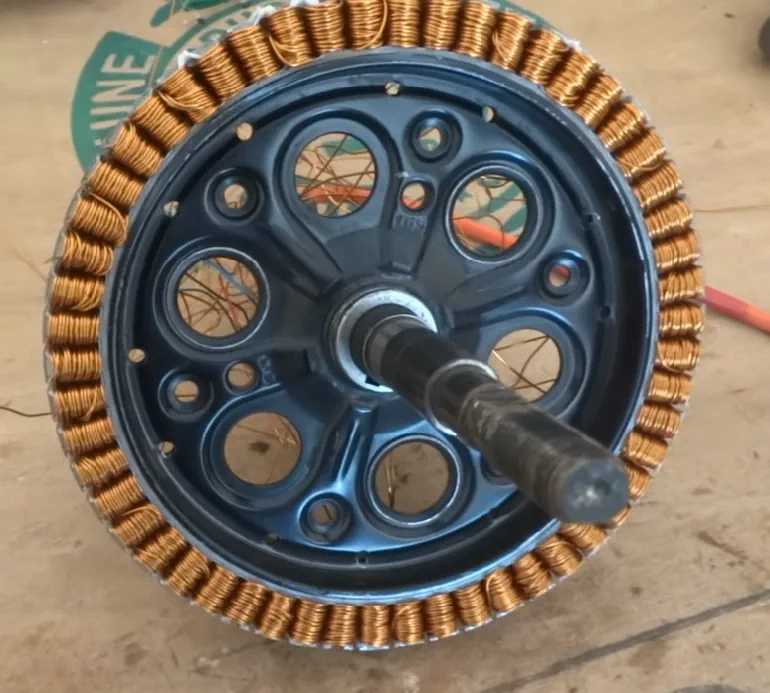

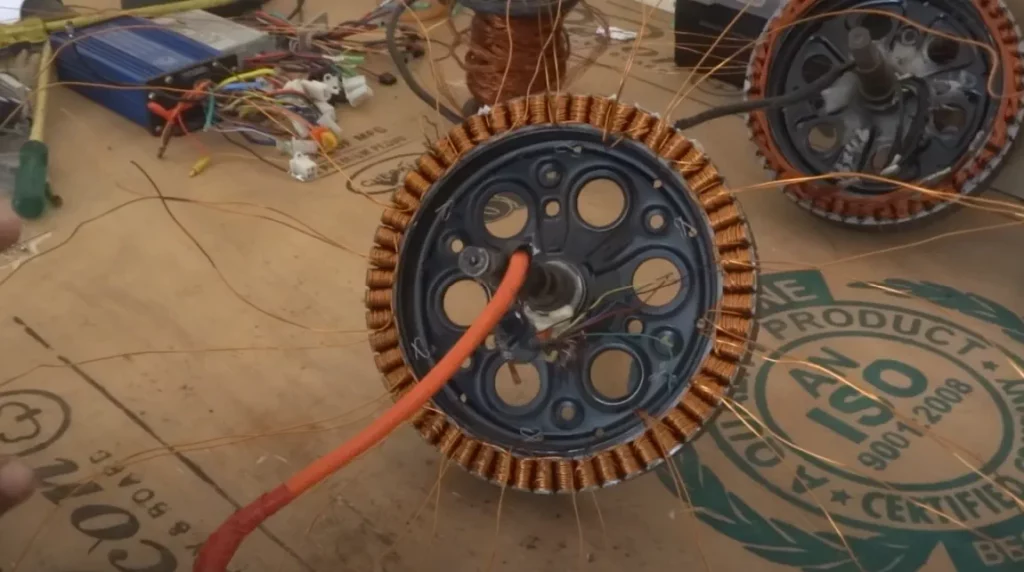

The brushless DC motor the most common motor consists of two cylinders, one inside the other.

The rotor (outer cylinder) is just a permanent magnet, and the stator ( the inner cylinder) is made out of coils of copper wires.

When power is applied to it, it will energize and become an electromagnet.

The rotor spins because the permanent magnet and electromagnet attract when one coil is powered.

As the rotor turns, the energized coil switches, creating a cycle that keeps the rotor in motion.

A helpful analogy is to think of a dog chasing its tail.

| Motor feature | Description |

|---|---|

| Motor Power | Motor power, measured in watts (W), indicates the energy output of the motor, affecting its work capacity. Higher wattage often leads to more powerful and faster operation. It’s a crucial metric in determining a motor’s performance and suitability for various applications. |

| Motor Torque | Motor torque, expressed in newton-meters (Nm), measures the motor’s rotational force. Greater torque results in improved acceleration and the ability to handle heavier loads or steep inclines. Torque is a key factor for assessing a motor’s strength. |

| Control Systems | Control systems in motors manage the speed, direction, and response to input. They incorporate features like regenerative braking, variable speed control, and responsiveness to user commands, contributing to a smoother and more efficient operation. |

| Speed and Acceleration | Speed represents the maximum velocity the motor can attain, while acceleration measures how quickly it can reach higher speeds. These factors significantly influence a motor-driven system’s response time and efficiency. |

| Hill Climbing | Hill climbing capability depends on the motor’s torque and power output, as well as its efficiency in tackling elevation changes. This aspect is especially important for vehicles and devices designed for off-road or hilly environments. |

| Motor Types | Motor types encompass various technologies, including brushed and brushless DC motors, AC motors, and more. Each type has its unique characteristics, such as efficiency, maintenance requirements, and suitability for different applications. |

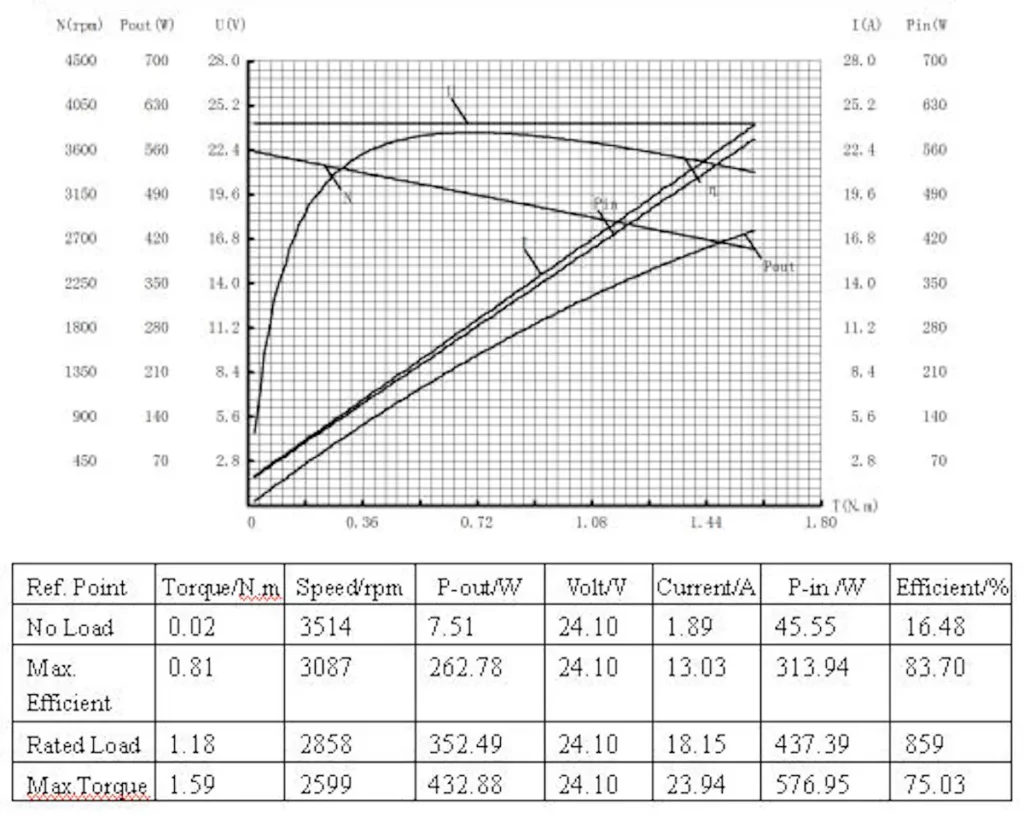

Manufacturers typically provide key motor specifications, including power in watts (real and/or peak), voltage in volts, RPM, and torque in Nm.

Electric scooter motor power

The most useful specification of an electric scooter motor is its power.

The motor power determines many of the performance features of the scooter. Higher motor power will typically result in:

- higher top speed

- better climbing angle

- higher load capacity

- to some extent, the longer range

Higher power levels will usually demand bigger batteries, meaning these models will tend to be heavier in weight.

Also, because of the bigger batteries, they will take more time to charge.

If you want a more scientific but simple explanation of power, here’s a great video.

Power levels in electric scooter motors

The power in adult electric scooters spans 80 all the way up to 12,000 Watts.

Budget and typical commuter scooters usually fall in the 200-500 Watt range, with common power levels at:

- 250 Watts (up to 15 mph / 25 kmh)

- 350 Watts (15-22 mph / 25-35 kmh)

- 500 Watts (over 25 mph / 40 kmh, some reach 38 mph / 60 kmh)

Electric scooters with power levels above 1000 Watts will frequently provide top speeds of at least 30 mph / 50 kmh. However, the way that brands and manufacturers report the power levels of their scooters can sometimes be misleading.

That brings us to the concept of real vs peak power in motors.

Real vs peak power

The amount of power a motor generates changes over time and depends on several other factors. The most important factor is the motor temperature, as motors start to become less performant as they heat up. That makes the difference between what’s known as real (continuous) and peak motor power.

In ideal conditions, the scooter can achieve its peak motor power, but real-world scenarios involve traffic, frequent stops, turns, hills, and obstacles, leading to the real motor power.

Some brands emphasize peak power without clarifying it, making it challenging to obtain real data. When only one power level is specified, it’s usually the peak power, although there are exceptions.

A practical estimate is that real power falls between 30% and 90% of peak power, with an average of about 57%.

If you want to find out the peak power of a scooter based on its real power, or the other way around, see the real and peak motor power converters.

Electric scooter motor torque

Torque is a very useful metric to determine how much work can the motor of an electric scooter perform.

Sadly, for some reason, very few manufacturers list this value.

Simply put, torque measures the tendency of a force that when applied to a body can cause it to rotate.

Motor types of electric scooters

Let’s see the common motor types in electric scooters, delving into their distinct characteristics and practical uses.

Hub vs chain-drive motors

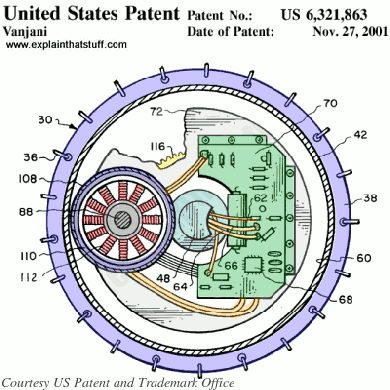

Many modern electric scooters today will come with hub motors. That means the motors are built into the hub of the wheel or wheels.

Hub motors and chain-drive motors are two distinct systems within electric scooters.

Hub motors, typically located within the wheel hub, simplify the scooter’s design by eliminating the need for chains and gears. This results in fewer breakdowns, easier repairs, and improved energy efficiency.

However, hub motors may have limitations in terms of torque and are generally heavier.

In contrast, chain-drive motors are positioned separately, often on the scooter’s deck. They offer efficiency advantages when configured properly and are generally more cost-effective.

Additionally, chain-drive motors provide greater customization options for adjusting speed and torque levels by changing sprockets.

It’s worth noting that hub motors tend to be less suitable for customizations and may pose challenges when replacing wheels.

Each motor type has its unique strengths and considerations, making the choice between them dependent on the specific scooter’s setup and requirements.

Geared vs gearless motors

Hub motors come in two primary types: geared and gearless.

Gearless hub motors, also known as direct-drive motors, utilize electromagnets to turn the wheel directly. In contrast, geared hub motors generate movement internally and transmit it to the wheel via a gear mechanism.

Gearless hub motors typically offer greater power, resulting in higher top speeds and improved climbing capabilities. However, they tend to be larger and heavier due to the need to rotate a single axle rapidly.

One advantage of gearless hub motors is their regenerative braking feature, which adds to their appeal.

Conversely, geared hub motors are generally less powerful but more energy-efficient due to their leverage mechanism. However, they have more moving parts, leading to increased wear and tear and potential maintenance issues.

One notable benefit of geared hub motors is their potential for longer range. These differences in motor types apply not only to e-bikes but also to electric scooters, providing users with valuable options for various needs.

The following video goes into detail about the differences between geared and gearless motors. It’s primarily about the motors in e-bikes, but the same principles apply to scooters as well. Take a look if you want to learn more.

Brushed vs brushless DC motors

DC, or direct-current motors, can come in two types: brushed and brushless.

There are not that many brushed motors anymore, as they are older technology.

They generate power with two sets of electromagnets. The larger one is in the form of an empty cylinder, and the second, smaller magnet is inside of it. The inside magnet is the one that gets rotated.

Its movement generates electromagnetic fields between the two magnets, which is then translated into the movement of the parts that rotate the wheel.

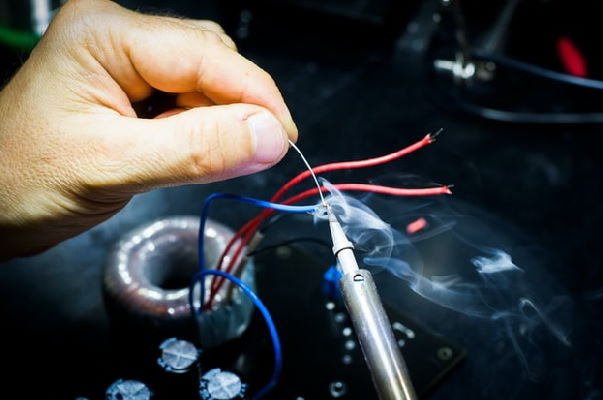

The electric current is being carried through carbon or graphite brushes, hence their name. These need to be replaced since they get worn out.

Brushless motors are a similar but simpler mechanism, that eliminates the need for brushes. They are more efficient, more reliable, and don’t require frequent repairs.

How to maintain the motor on my electric scooter?

Just common-sense general maintenance and taking care of your scooter will be enough for most scooters, as the majority will have brushless DC hub motors that require no maintenance.

To extend your scooter’s lifespan, avoid constant top-speed riding and excessive hill climbs.

Most modern brushless hub motors require little to no maintenance. While an annual checkup at a repair shop is wise, these motors don’t need brush replacements.

Hub motors, especially gearless ones, are durable and low-maintenance, outlasting common electronic issues. In essence, well-maintained motors can run reliably for years with minimal care.

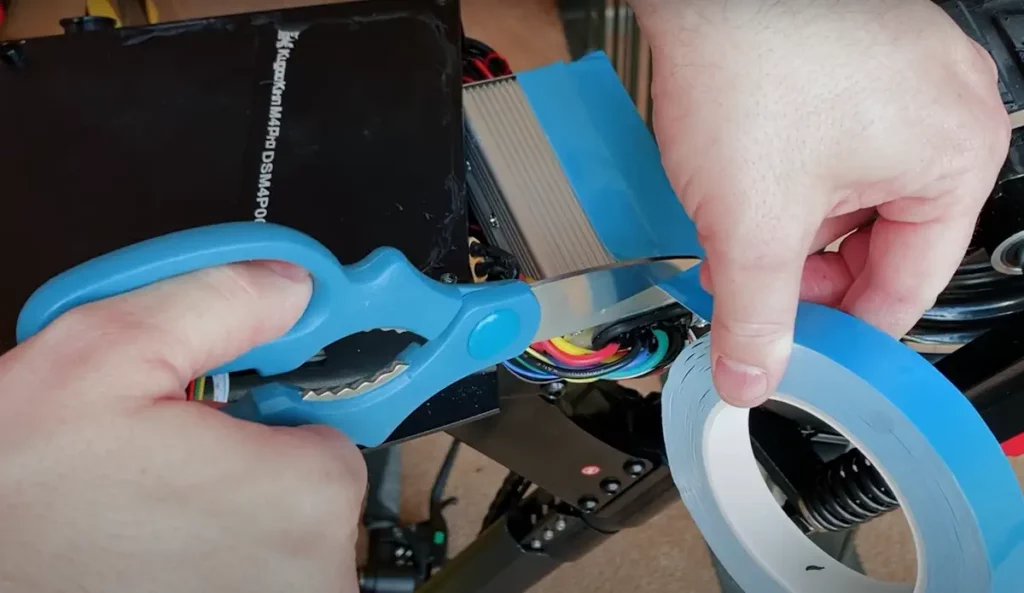

If your scooter has a chain-drive motor, your only job will be to grease the chains once every few months, to make sure everything runs smoothly. But, out of the 300+ electric scooter models today, only a handful of popular ones still have chain-drive motors (most notably the Razor E300, and some other Razor models).

If you want to learn how the motor works in concert with the rest of the parts in the electric scooter, check out the full guide here.

FAQs

Every electric scooter includes a motor by definition. The same goes for the battery and the controller.

Today, most electric scooters will have hub motors, which are motors embedded in the wheels. Newer models will tend to have brushless DC motors.

The most powerful electric scooter motors come from Minimotors USA and Rion (Dualtron X2 and Rion2 RE90). The Rion2 RE90 has a peak power of 12,000 Watts, making it the world’s fastest electric scooter, reaching speeds up to 100 mph (160 km/h).

An electric scooter with a 5000W motor can reach speeds of 40-50 mph (64-80 kmh) or higher, depending on the model and other factors.

An electric scooter with a 1000W motor typically reaches speeds of around 20-30 mph (32-48 km/h), but the actual speed can vary depending on factors like scooter design and rider weight.

To check if your scooter’s motor is the issue, listen for unusual noises, inspect wiring, ensure the battery is healthy, monitor motor heat, compare performance to specs, and look for error codes. If in doubt, consult a technician.

Yes, you can tune up the motor for improved performance by adjusting settings and maintenance, but it’s crucial to proceed with caution, follow safety guidelines, and consider warranty implications. Consulting experts is wise for effective tuning.